WelderDestiny › Welding Procedure › Welding Heat Input

Welding Heat Input Essential Variable

Many welding codes require the measuring and control of welding heat input during the procedure qualification process, and later in production welding. In particular, the welding heat input is an essential variable often associated with the impact properties of welds.

Typically welding codes such as ASME IX has the welding heat input as a supplementary essential variable. This means that you only need to control it if your product's design calls for defined minimum impact properties.

Other codes may not actually define the welding heat input as a specific essential variable, but requires you to control the heat input base variables of Voltage, Amperage and welding travel speed.

The fundamental thinking behind the importance of the welding heat input, is that as the heat input increases, the cooling rate of the weld is reduced. With a reduced cooling rate, most materials will exhibit increased grain size in the weld and heat affected zones (HAZ) of the base metal. Increased grain size is associated with reduced impact properties.

Another effect of reducing the cooling rate is that certain hard brittle phases, such as martensite, can be prevented from forming. When welding materials that are prone to hardening, and suffering from hydrogen assisted cold cracking, (click here to learn more about HACC...) then it may be important to increase the heat input above a certain minimum value.

In other words, sometimes we would like to make sure that we remain below a maximum heat input level, and sometimes we want to make sure that we remain above a minimum heat input level.

We will however see that there is more to this welding heat input parameter than meets the eye, and that under some circumstances we can be led to incorrect conclusions regarding the effect of the change in voltage, amperage and travel speed.

The WelderDestiny Compass: Weekly e-zine Subscription

You can take a look at "The WelderDestiny Compass" back-issues by clicking here.

DBTT VS Grain Size: Ferritic steels exhibit a transition temperature below which they become brittle. This is known as the Ductile to Brittle Transition Temperature (DBTT). This graph shows how the DBTT reduces with reduced grain size. In effect, a smaller grain size increases the toughness of the steel.

DBTT VS Grain Size: Ferritic steels exhibit a transition temperature below which they become brittle. This is known as the Ductile to Brittle Transition Temperature (DBTT). This graph shows how the DBTT reduces with reduced grain size. In effect, a smaller grain size increases the toughness of the steel.Welding Heat Input Defined

In short, the welding heat input is defined as the amount of energy that is used by the welding process to deposit a specific length of weld.

The usual practice is to express the energy in terms of "Joules". In the equations, it will be shown as "J". Often this is changed to kilo Joules, (kJ) in which case the Joule value is divided by 1000. The length can typically be inches (in) or millimetres (mm) or centimetres. (cm) The most common usage is inches for those working in imperial units (e.g. USA) and millimetres for those working in SI units. (Most of the rest of the world!)

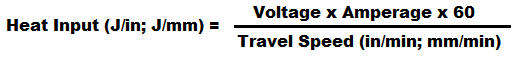

The most common equation used for calculating the welding heat input is:

This equation is widely used, but it does have its limits. If the welding is being done with a power source that delivers a varying (or pulsed) voltage or amperage, then it is difficult to use that first equation. Under those circumstances, the energy is often measured as an "instantaneous" measure. Some computerized power sources will give you this number, or you can measure it using some welding parameter recording equipment.

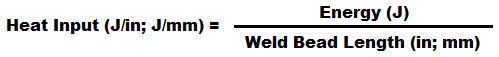

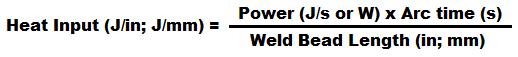

These instantaneous measurements will typically be provided as the total energy used (in Joules) to deposit a weld bead, or it could be provided as the Joules per second (J/s) or Watts (W) used while depositing the weld bead. If that is the information you have, then you can use the following welding heat input equations.

First, for using the "instantaneous energy" measurement:

Next, for using the "instantaneous power" measurement:

Theoretically all of the equations given above will give you the same answer.

Now, let us just look at that first equation, and see what it is telling us. In summary, it is showing us that we can keep a stable heat input (HI) while increasing the welding voltage or amperage, as long as our welding travel speed is proportionately faster. This in turn suggests that we can end up with the same weld microstructure and mechanical properties, even if we change the welding parameters, as long as we just keep the welding heat input steady. A little later we will see that that assumption is not entirely correct.

Effect of Welding Process

What the equations shown above does not take into account, is that different welding processes have different thermal efficiencies. These are also termed "arc efficiencies". What the arc efficiency shows is how much of the energy is actually used to heat up the base metal, and melt the filler metal. An arc efficiency of 1 would indicate that 100% of the energy is used, while an arc efficiency of 0.5 would indicate that 50% of the energy is used, and 50% is lost to the environment in an unproductive way.

Some typical arc efficiencies are: Plasma Arc Welding (PAW): 0.46; Gas Tungsten Arc (GTAW): 0.65; Gas Metal Arc (GMAW) and Submerged Arc (SAW): 0.83.

So, if we want to compare the welding heat inputs between two different welding processes, then we really need to also factor in the arc efficiency of the different welding processes.

The welding codes almost never factor in the arc efficiencies of the different welding processes. This is understandable, because the situation is such that the heat inputs are generally not used to compare different welding processes within the welding code context. Welding parameter ranges are generally limited to each welding process. The codes therefore just assume that the arc efficiencies are 100% for all the processes, both during procedure qualification and production welding.

If on the other hand we need to compare welding heat inputs between welding processes, then we do need to consider the arc efficiencies of the different processes.

Melting Efficiency

Let us look at the first heat input calculation again. Let us assume that we are using the GTAW process to weld onto a thick copper plate. Due to the high thermal conductivity of copper, a lot of the heat is rapidly conducted away from the area under the arc. It would be possible to reduce the voltage and amperage to the point where the copper base metal does in fact not melt significantly. Under such a circumstance, I could have a zero welding speed and not even have enough energy entering the base metal to melt it. Under this scenario, we actually have an infinite heat input, while not even doing any constructive work. In this instance, the "melting efficiency" of our welding process and parameters is zero, because none of the energy is actually going into melting base metal or filler metal.

If we now increased the voltage and amperage significantly in our copper plate scenario, we will start achieving some significant melting of the base metal, and we can start to have a reasonable welding travel speed. Now our heat input will reduce significantly while actually doing some significant welding work. We now have a greater melting efficiency, even though our heat input is actually lower.

This example shows us that there is more going on than just assuming that the heat input always gives us the same result, regardless of how we get to the answer. We also need to think of the "melting efficiency". The melting efficiency is the amount of the energy that is actually used to melt the base metal and filler metal. The rest of the energy is lost to heating the base metal and the environment, without contributing to melting of the metal.

So, if we think about this we will see that as we increase the amount of energy entering the material in any time period, more of this energy will be used to melt the base metal and the filler metal, because the base metal is unable to conduct the heat away fast enough. Another way of saying this is that the thermal gradient in the material is higher with higher energy per time (Watts) input.

In other words, increasing the volts and amps will lead to greater penetration and also faster cooling rates than when we use lower volts and amps, even if the welding heat input remains the same by altering the travel speed to compensate.

This influence becomes significant when we drastically alter volts and amps and travel speed compared to that used in the welding procedure qualification coupon. When the changes to these welding parameters are moderate, then this effect is not very significant. Some welding codes therefore just control the welding heat input by setting reasonably tight limits on the qualified ranges for the volts, amps and travel speed.

Controlling Heat Input In The Field

Welding heat input is one of the most difficult parameters to control out in the field, because we can only decide if the required heat input has been achieved in hindsight. During the welding, we can monitor the volts, amps and travel speed, but only after the weld run has been completed can we perform the calculation to see if we have actually achieved the required heat input limits.

Not only is this process tiresome, but it leads to all kinds of issues when we find that the deposited weld bead had been welded with a heat input value outside the allowable limits. What is the best way forward? Grind out the offending weld bead? There is no one single answer, because there are numerous situations where the control of the welding heat input is important for different reasons. Typical reasons are:

- To reduce the probability of hydrogen assisted cold cracking (HACC) when welding certain steels.

- To ensure high enough toughness properties in ferritic materials.

- To reduce the formation of constituents in the microstructure of stainless steels that can reduce their corrosion resistance. (e.g. Sensitization of stainless steels, or formation of inter-metallic phases in duplex stainless steels.)

- To reduce the base metal temperatures, to reduce surface oxidation during welding. Typically of stainless steels, titanium and nickel based alloys.

Depending on the situation, different remedial actions will be appropriate. It is also important to remember that a certain level of pragmatism is needed, because a single weld run in a multi pass weld may have a negligible effect on the weld as a whole. Always keep in mind that welding is a statistical process. We are working with probabilities, not absolutes.

Given the difficulties of controlling welding heat input in the field, I have developed a smartphone app to assist. It is called the "Heat Input Helper". This app allows you to enter the target maximum and minimum heat inputs, and then entering the voltage and amperage the welder is using to weld. The start button is pushed when the welder strikes his/her arc, and the app shows how far the welder should have welded during any given time to remain within the heat input limits. It therefore, very speedily, becomes obvious when the travel speed is outside the required range.

The app has been written with a delay function so that Welders can actually use it to time themselves. This is useful when Welders want to "practice" to weld within a certain heat input range.

At this stage you can download the app from the Google play store...

You can give the Heat Input Helper a "test drive" here...

Welding Heat Input Essential Variable Summary

Welding heat input is certainly an important variable to monitor and control. For some applications you will want to make sure that your welding heat input is high enough, to prevent excessive hardness, and for other applications you will want to make sure that the heat input is low enough to ensure good corrosion resistance and toughness.

Many welding codes require that you limit your heat input when impact properties are important for your application. It then becomes a supplementary essential variable.

While it may appear that a given heat input is always the same, irrespective of how it is achieved, this is not so. To find out more about this aspect of arc efficiencies and melting efficiencies, click here to read a good paper on the AWS website coving the subject.

While the heat input calculation is not all that difficult, it is very difficult to control out in the field. Most of the time it can only be calculated in hind sight, after the weld bead has already been deposited.

The Heat Input Helper smartphone app has been developed to help you control the heat input out in the field.

WelderDestiny › Welding Procedure › Welding Heat Input

The WelderDestiny Compass: Weekly e-zine Subscription

You can take a look at "The WelderDestiny Compass" back-issues by clicking here.