WelderDestiny › Certified Welder › Welder Essential Variables

Welder Essential Variables

Welder essential variables are specified within the welding codes. (Click here to read more about welding codes.) The welding codes specify the types of tests that Welders need to do to become "qualified Welders". (Click here to read more about typical Welder coding tests.) Once the Welder has been successfully coded, the question arises as to what the qualification actually covers. This question is answered within the codes by listing welder qualification essential variables and the associated qualification ranges.

The WelderDestiny Compass: Weekly e-zine Subscription

You can take a look at "The WelderDestiny Compass" back-issues by clicking here.

For

each code these welder essential variables will be slightly different, and the

qualified ranges will be different. It is not the intention of this web page to

go into a full interpretation of all the different codes and their essential

variables and qualified ranges. To get that information, you will need to look

at the relevant welding code. The intention of this web page is to list the

typical Welder qualification essential variables, and to discuss why they are

listed in the welding codes.

Where

there are designations associated with the different welder essential variables, we

will list the typical American and European designations. The European

designations, when applicable, are listed second.

Welders Performing Double Jointing on a Lay Barge With Submerged Arc Welding (SAW)

Welders Performing Double Jointing on a Lay Barge With Submerged Arc Welding (SAW)Welding Process

Each

welding process requires different skills, hence this is one of the Welder essential variables.

Typical welding processes are:

- Oxyfuel Gas Welding (OFW / 311): This is the "old fashioned" flame welding using a "blow torch".

- Shielded Metal Arc Welding (SMAW / 111): Also called Manual Metal Arc Welding (MMAW) or stick welding.

- Submerged Arc Welding (SAW / 121[Solid Wire] & 125[Tubular Wire]): In this welding process the welding arc is "submerged" below a covering of flux powder.

- Gas Metal Arc Welding (GMAW / 131[MIG] & 135[MAG]): Also called Metal Inert Gas (MIG) or Metal Active Gas (MAG) welding. This obviously depends on whether an inert or active gas is being used for the shielding.

- Flux Cored Arc Welding (FCAW / 114[Self Shielded] & 136[Gas Shielded]): In some codes FCAW and GMAW are considered the same process, with the type of wire being an additional essential variable that distinguishes them apart.

- Gas Tungsten Arc Welding (GTAW / 141[Solid Wire] & 142[No Wire] & 143[With flux cored wire] & 145[Using reducing gas]): Also called Tungsten Inert Gas (TIG) welding.

- Plasma Arc Welding (PAW / 15): PAW looks similar to the GTAW welding, but there is an additional plasma gas that is introduced. The melting of the metal is primarily achieved by the plasma gas rather than directly by the arc.

Please

note that the numbered designations above are the European designations.

Machine and automatic welding processes such as Electron Beam Welding (EBW) or

LASER Beam Welding (LBW) and the like are not listed here, as these are dealt

with in a different way to the skill based welding processes.

As

a general rule, each process will only qualify you to weld with the process you

used in the coupon. It is very possible to use more than one process in each

coupon. Two processes per coupon is quite common. (e.g. GTAW root and SMAW

filler and cap.) Now and again 3 processes are used, to get the most “bang for

your buck” out of the qualification process. (e.g. GTAW root, SMAW filler and

FCAW filler and cap.) Practically it would be very rare to weld a Welder

qualification coupon with more than 3 processes.

Backing

Backing

is when the weld is deposited against something that can contain the welding

arc and weld pool in the root of the joint.

When

a joint is welded from one side only, and the weld needs to be full penetration

without backing, then it takes a lot more skill than if the joint can be welded

from both sides. Welding with or without backing is therefore an important

Welder essential variable.

As a general rule, if the Welder qualification was welded without backing, then you will be qualified to weld with or without backing, but not visa-versa.

Deposited Weld Thickness

When

performing multi pass welds, a welder that lacks skill will end up with very

uneven weld layers. As the thickness increases, this can lead to a very

unsightly weld that leads to areas where slag can easily be trapped, and an

uneven cap. If a Welder can show that s/he has the skill to weld above a

certain thickness, then further increases in thickness will not be giving much

additional information from a skill perspective. For this reason, there tends

to be a maximum thickness of deposited weld metal given in the codes above

which all thicknesses are qualified. For ASME IX this is 13mm. For deposited

thicknesses below 13mm, the Welder is generally qualified to weld up to 2 times

the deposited thickness within the coupon.

When

welding a coupon with more than one welding process, the deposited thickness

for each process is taken separately.

For particularly thin materials, the Welder may need to show that s/he is capable of welding such a thin material. Many codes that assume you are only going to be welding relatively thick materials (e.g. ASME IX) do not specify a minimum thickness to which the welder is qualified.

Another

complication to take note of, is that if you are using the short circuiting

mode of transfer (see lower down this page for transfer mode explanation) for

the GMAW process, then the qualified thickness is further limited.

Close Up View of Off-Shore Pipeline Double Jointing With SAW Process

Close Up View of Off-Shore Pipeline Double Jointing With SAW ProcessPipe Diameter

As

a pipe's diameter decreases, it becomes more difficult to weld. The welder will

therefore need to display that s/he can weld down to the smallest diameter that

needs to be welded on the production work. Many codes tend to specify a number

of diameter ranges, to make this welder essential variable easier to implement and

control. Above a certain diameter, (different codes have different ideas about

what that diameter is) the difficulty will not really change much, hence the

approach is that even if the coupon welded was larger in diameter (or even a

plate) then the Welder can weld down to that specified diameter.

As an example, in the ASME IX code the diameter ranges are:

- Less than 25mm qualifies from the diameter welded and larger.

- 25mm to 73mm qualifies from 25mm diameter and larger.

- Over 73mm qualifies from 73mm diameter and larger.

Please note that other codes have different ranges, but I think you get the general idea.

Type of Base Metal

Different base materials can require different skills to weld. For this reason, the material/s welded in the coupon are essential variables for the Welder qualification. Generally the codes tend to group together different materials that have a similar weldability from a skill perspective. In the ASME codes the materials are given "P" numbers, (ASME IX, Table QW/QB-422 lists these P numbers) and in the European codes they are given "group" numbers. (ISO 15608 lists the different Groups.)

A few examples of the material groupings are:

- Carbon steel: P1 (ASME) / Group 1.1 (ISO)

- Type 304 Stainless Steel: P8 (ASME) / Group 8.1 (ISO)

- Duplex Stainless Steel: P10H (ASME) / Group 10.2 (ISO)

- Alloy 800 Nickel based alloy: P45 (ASME) / Group 45 (ISO)

From the examples listed above, we can see that the ISO designations have started to largely mirror the ASME system, with some variations.

Also

note that the qualified ranges are often wider than just the single group

within which the coupon was welded. As an example, within the ASME IX code, a

welder qualified on a P1 material is qualified to weld all materials P1 to

P15F, P34 and P41 to P49. This is a very wide array of base materials qualified.

(Carbon steels, low alloy steels, stainless steels, Copper Nickel and Nickel

based alloys.) It may seem that one test piece can allow the welder to weld

almost anything, but the "problem" is that this should be seen within

the context of the filler metal welder essential variable, because the different

materials will need different filler metals to weld. The EN 287-1 code does not

give such wide ranges, but in essence once the filler metal variable is brought

into the picture there is not such a big difference between the two systems.

In the structural steel welding codes, welding on one of the base materials listed in the code typically allows the Welder to weld on all the other materials listed in the code. This approach is possible because the scopes of the structural codes in terms of materials are very limited.

Type of Filler Material

The skill required to weld with different filler materials can vary in different ways depending on the type of welding process and the filler metal composition itself. Typically the effects are as follows:

- Welding processes that use flux can have significantly different flux types. For instance, SMAW electrodes for welding steels can have flux coverings that result in a very hard "digging" arc with fast freezing flux, (e.g. E6010) or a mild arc with fast freezing flux (e.g. E6013) or a low hydrogen flux, (e.g. E7018) or a flux that contains a lot of iron powder. (e.g. E7024) Each of these different fluxes requires the welder to master different skills to weld successfully.

- The type of alloy of the filler metal can also have a significant effect. As an example, materials with high Nickel contents tend to be more viscous wen being welded, so they are much less fluid and do not flow well. The Welder needs to move the arc to actually push the weld metal in the right direction. The Welder cannot rely on the surface tension to move the molten weld metal like when welding steel. So, each material does have its own issues.

Based on the interaction of the two factors listed above, the codes classify filler materials into groups based on their weldability from a skill perspective. Within the ASME codes, filler materials are grouped as "F" numbers. EN 287-1 groups the filler metals based on the type of flux covering, or for wires without flux coverings, the classification is based on whether the wire is solid, metal cored or flux cored.

The welding code will then give qualified ranges for the filler materials qualified. Generally the code will make a call on which filler materials are more difficult to weld with, and then allow the Welder to also weld filler materials that requires a lower skill level.

Welding Position

Welding position is one of the main welder essential variables used by all the codes. It

is obviously much more difficult to deposit a weld which is in the vertical

position than a weld that is in the flat position. In the case of the

vertically oriented weld, the liquid weld pool will want to follow gravity and

make its way to the floor. The weld pool for the weld in the flat position will

just be drawn into the weld preparation by gravity, so will be much easier for

the Welder to control.

Most codes have similar requirements for weld positioning and the subsequently qualified ranges. Different codes do however use somewhat different designations for the different weld positions. ASME IX differentiates between production positions and test positions.

The

production positions are:

- Flat (F)

- Horizontal (H)

- Vertical (V)

- Overhead (OH)

The

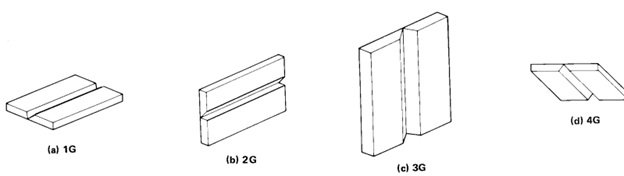

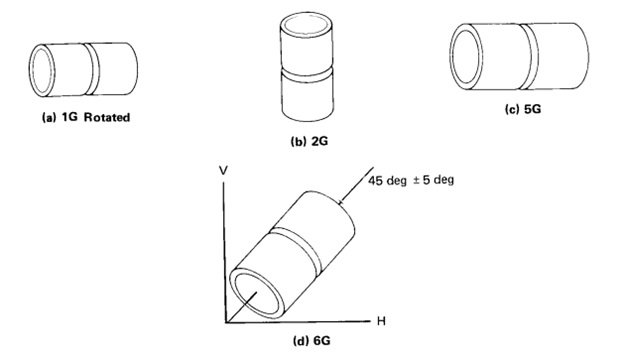

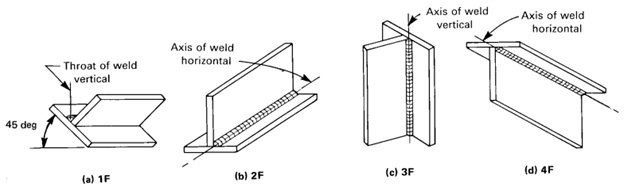

test positions are given more unique identifiers as shown in the sketches

below: (The "G" in the designations refer to groove weld test

positions, and the "F" designations refer to fillet weld test

positions.)

Test Positions for Plate Groove Welds

Test Positions for Plate Groove Welds Test Positions for Pipe Groove Welds

Test Positions for Pipe Groove Welds Test Positions for Plate Fillet Welds

Test Positions for Plate Fillet WeldsFor

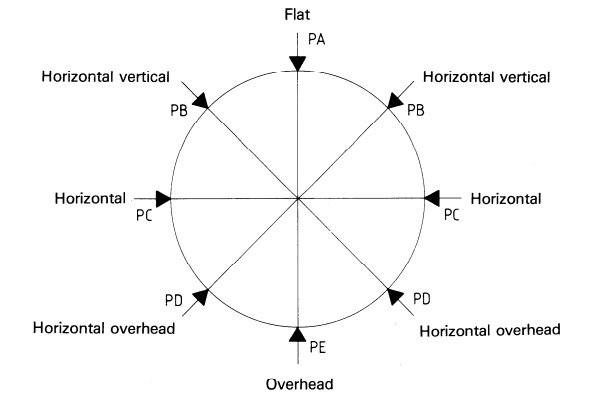

the European codes, the welding positions and symbols are detailed in ISO 6947.

The production positions are summarized in the sketch below:

Welding Production Positions from ISO 6947

Welding Production Positions from ISO 6947There

is more to the European designations for position than shown in the sketch

above, but I don't think that more detail will add too much value and is

therefore not warranted here. The qualified ranges for EN 287-1 is quite

similar to that in the ASME IX code.

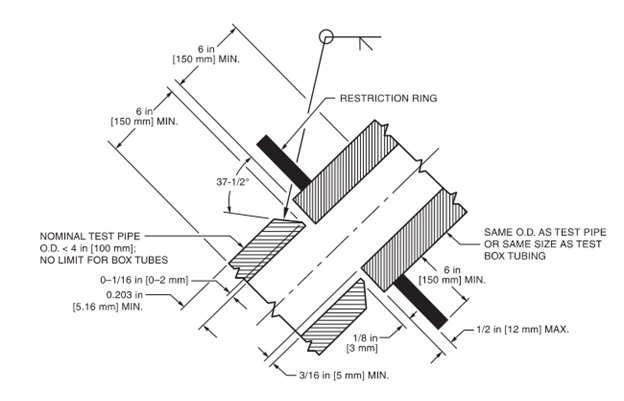

Besides

just the normal test positions shown above, some codes also introduce

restrictions as part of their test positions. This is typical for codes dealing

with boilers (Where spaces between boiler tubes can be very small.) and also

structural codes. (Where tubulars intersecting at tight angles can restrict the

Welder's access to the root of the joint.) Often an "R" designator is

placed behind the test position to indicate that it has been welded in the

restricted position. See the sketch below for a typical AWS D1.1 test joint for

a 6GR test.

AWS D1.1 - 6GR Test Position

AWS D1.1 - 6GR Test PositionWelding Progression

Another

aspect associated with the position of the test coupon is the direction of the

welding. Normally this is termed the "progression" of the welding.

The two possibilities being either an uphill progression or a downhill

progression.

Most

of the time Welders will need to weld in the uphill progression. As an example,

if the Welder needs to weld a pipe girth weld with the pipe's axis in the

horizontal direction, (5G test position) and starts welding from the bottom of

the pipe and progresses upwards to the top of the pipe, it will be called an

uphill progression.

The

most common circumstance for doing downhill progression is when performing high

productivity welding on pipelines. Here the Welder typically starts welding on

the top of the pipe and progresses downward to the bottom of the pipe. This is

often called "stovepipe welding". The main reason for welding in the

downhill progression is that it leads to much faster travel speeds and more productive

welding.

Most

codes will only allow you to perform production welding in the welding

progression you used in the Welder qualification test coupon.

Backing Gas

For

welding processes such as GTAW and GMAW, you will need to provide a gas on the

back side of the weld when performing a single sided weld in alloys that easily

oxidize when hot. This situation is typical for welding stainless steels,

nickel based alloys and titanium alloys amongst others. The shielding gas

provided on the back side of the weld is called a backing gas.

Most

of the codes will require that if you welded the Welder qualification coupon

using a backing gas, then you are only qualified to weld with a backing gas. If

you welded without a backing gas then your qualification range will be: With

backing gas and Without backing gas.

Welder Remotely Welding Double Joint Internally With SAW

Welder Remotely Welding Double Joint Internally With SAWTransfer Mode

The transfer mode deals with the way in which molten weld metal is transferred from the consumable electrode to the weld pool. It is only applicable for some of the welding processes. When

welding with Gas Metal Arc Welding, (GMAW) there are different transfer modes

possible depending on the interaction of the following:

- The welding voltage.

- The welding current.

- The shielding gas.

The

different transfer modes are:

- Short circuiting mode: Also called dip transfer. Here the wire dips into weld pool and causes a short circuit, extinguishing the arc momentarily. Resistive heating in the wire then causes the wire to melt back and the arc is re-established. As a general rule this occurs at voltages below 19V or so. The disadvantage of this transfer mode is that most of the heat goes into the wire, so it can easily lead to lack of fusion defects. The big advantage is that it is a low energy mode, so it is easier to control, especially when welding thin materials or when welding out of position.

- Globular transfer mode: When the voltage is increased, the weld metal is transferred in globules. This mode can be a bit messy, as the amount of spatter increases significantly. It is also possible to weld out of position with this mode of transfer.

- Spray transfer: Spray transfer is only possible if the inert gas content of the shielding gas is high enough. The general rule is that the Argon (Ar) and Helium (He) contents should be above 85%. Once the voltage reaches around 28 to 30V, then the weld metal transfers across the arc in a stream of particles. This is a high energy mode of transfer and most materials cannot be welded out of position with spray transfer. The notable exception being aluminium.

- Pulsed Spray: When the power source is set such that the voltage is constantly fluctuating between the parameters associated with dip transfer and spray transfer, then pulsed spray is experienced. The big advantage of pulsed spray is that it mostly eliminates the lack of fusion problem of dip transfer while allowing out of position welding.

Strictly speaking there is also a high energy axial spray transfer mode, but this is not usual for manual welding, so is not dealt with here.

As a general rule, the codes lump globular, spray and pulsed spray together while keeping dip transfer separate. This is in recognition of the additional skills needed to perform dip transfer welding without getting the lack of fusion defects. So, the qualified ranges are typically that dip transfer qualifies you only for dip transfer, and welding with one of the other modes qualifies the Welder to weld any of those other modes of transfer.

A

note regarding the transfer modes of Flux Cored Arc Welding (FCAW) is probably

in order here. There is much written about different transfer modes for FCAW,

but my personal experience is that there is really not much in it. Personally

as far as I am concerned, FCAW always delivers a globular mode of transfer. I am sure that there will be those that disagree with me on this point.

Autogenous Welding

Some

welding processes do not use a consumable electrode. This means that they allow

you to weld without adding any filler metal. This is called autogenous welding.

GTAW and PAW are examples of such welding processes.

When

welding the coupon without filler you will generally only be qualified to weld

autogenously. Conversely, to perform autogenous production welds, you will need

to weld a coupon without filler.

Inserts

Apart from fusing the two parts of the joint without adding any filler, welding processes that allow autogenous welding also allow you to use separate pieces of metal that are placed in the joint and then fused. Typically these would be in the form of a ring of metal placed in the root of a pipe but joint, and then melted along with the ends of each pipe to complete the weld root. These additional “pieces of metal” are called inserts.

The

main reason for using inserts is that it makes welding a single sided root in a

pipe easier. It does however take some know-how to do this, so there is a

specific skill involved. As a general rule, when you welded the coupon with an

insert, then you will only be qualified to weld with an insert. Conversely, you

will not be qualified to weld with an insert without doing a qualification coupon using one.

Welding Current and Polarity

The

two different types of current being referred to in welding is either

Alternating Current (AC) or Direct Current. (DC) Within DC, there is also the

possibilities of having either Direct Current Electrode Negative (DCEN – Also

called straight polarity.) or Direct Current Electrode Positive. (DCEP – Also

called reverse polarity.)

While

many cheap home welding power sources only deliver AC, in serious welding AC is

seldom used. There are some exceptions, with the notable exception being the

use of AC in GTAW welding of aluminium alloys.

By

changing the polarity of DC between electrode negative or electrode positive,

the ratio of energy going into the electrode verses the base material can be

changed. Welding with different current and polarity types require somewhat

different skills for some of the welding processes, (e.g. GTAW) hence the

introduction of this essential variable for Welders.

We

have just looked at the most common Welder essential variables listed in the

welding codes. Some codes will have some additional essential variables. Each

code also deals with the essential variables in slightly different ways, but

the summary of essential variables given above is a good basis for

understanding why codes have the qualified ranges that they do.

WelderDestiny › Certified Welder › Welder Essential Variables

The WelderDestiny Compass: Weekly e-zine Subscription

You can take a look at "The WelderDestiny Compass" back-issues by clicking here.